How to Measure Diameter? Easy & Accurate Methods

To measure diameter, use a ruler or caliper to find the distance across the center of a circle. The measurement represents the diameter of the circle.

Measuring diameter accurately is crucial in various fields such as engineering, architecture, and manufacturing. Whether determining the size of a pipe, a piece of machinery, or a circular structure, understanding how to measure diameter correctly ensures precision in calculations and designs.

By following simple steps and using the right tools, you can obtain accurate diameter measurements for your projects. Let’s explore the importance of measuring diameter correctly and the methods to achieve precise results in different applications.

Introduction To Diameter Measurement

Diameter measurement is crucial in various fields. To measure diameter accurately, use a caliper or ruler to gauge the width of a circle. Simply place the measuring tool across the center of the circle and read the measurement where it aligns with the circle’s edge.

Diameter measurement is a crucial aspect of many manufacturing processes. It involves determining the width of a circular object or cross-section. The accuracy of this measurement is essential for ensuring the quality and consistency of the final product. In this post, we’ll explore the importance of accurate diameter measurement and the various applications of this technique in different industries.

Importance of Accurate Diameter Measurement

Accurate diameter measurement is critical for ensuring the quality and consistency of manufactured goods. Even small variations in diameter can have a significant impact on the final product’s performance. For instance, a tiny difference in the diameter of a ball bearing can cause it to malfunction or wear out prematurely. Therefore, it’s essential to use precise measuring tools to obtain accurate diameter measurements.

Applications in Various Industries

Diameter measurement has a wide range of applications across various industries. In the aerospace industry, for example, accurate diameter measurements are necessary for manufacturing turbine blades and other critical components. Similarly, the automotive industry relies on precise diameter measurements for producing engine parts, wheels, and tires. Other industries, such as construction, electronics, and healthcare, also use diameter measurement techniques to ensure product quality and consistency.

To summarize, diameter measurement is a crucial aspect of many manufacturing processes. Accurate measurements are necessary for ensuring the quality and consistency of the final product. With the right tools and techniques, diameter measurement can be used across various industries to improve product quality and efficiency.

Credit: www.discountramps.com

Basic Concepts

The measurement of the diameter is a fundamental concept in geometry and engineering. Understanding the basic concepts of diameter, radius, and Pi is crucial for various applications, from construction to manufacturing. Let’s delve into the key concepts that form the foundation for measuring the diameter.

Understanding Pi And Its Role

Pi (π) is a mathematical constant representing the ratio of a circle’s circumference to its diameter. It is approximately equal to 3.14159. The value of Pi remains constant, regardless of the size of the circle, making it an essential component in calculating the diameter of a circle.

Difference Between Diameter And Radius

The diameter of a circle is the distance across the circle passing through its center, while the radius is the distance from the center to the circle’s edge. In simple terms, the diameter is twice the length of the radius. Understanding this distinction is vital for accurate measurements and calculations in various fields.

Tools For Measuring Diameter

Accurate measurement of diameter is essential in various industries and applications, such as engineering, manufacturing, and construction. Having the right tools for measuring diameter ensures precise results, enabling professionals to make informed decisions and achieve optimal outcomes. Two commonly used instruments for measuring diameter are calipers and micrometers.

Calipers: A Precision Instrument

Calipers are a versatile and widely used tool for measuring diameter. They consist of two arms or jaws, one fixed and one movable, connected by a pivot. This design allows for precise measurement of both internal and external diameters. Calipers can be either analog or digital, with the latter providing a more accurate and easy-to-read measurement.

Using calipers to measure diameter involves placing the object between the jaws and gently closing them until they make contact with the surface. The measurement can then be read from the scale or digital display. Calipers are particularly useful for measuring larger diameter objects, such as pipes, rods, or cylindrical components.

Micrometers For Small Diameter Objects

Micrometers are highly precise instruments used for measuring small diameter objects. They consist of a calibrated screw mechanism with a measuring spindle and an anvil. Micrometers can measure both external and internal diameters with exceptional accuracy, making them ideal for applications that require precise measurements, such as machining and quality control.

To measure diameter using a micrometer, the object is placed between the spindle and anvil, and the screw is turned to bring the measuring surfaces in contact with the object. The measurement can then be read from the micrometer’s scale or digital display. Micrometers are commonly used in industries like aerospace, automotive, and electronics, where precision is paramount.

Both calipers and micrometers are reliable tools for measuring diameter, offering different levels of accuracy and suitability for specific applications. By using these instruments correctly, professionals can ensure precise measurements and achieve optimal results in their work.

Credit: www.insight-security.com

Using A Ruler Or Tape Measure

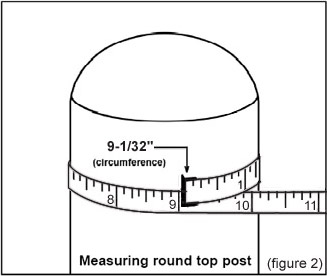

Measuring the diameter of an object accurately is essential in various fields, such as engineering, construction, and crafts. One of the simplest and most convenient ways to measure diameter is by using a ruler or tape measure. This method is widely accessible and can be done by anyone without the need for specialized equipment.

Step-by-step Guide To Manual Measurement

- Start by selecting a ruler or tape measure that is long enough to span the diameter of the object you wish to measure. Ensure that the ruler or tape measure is straight and free from any bends or deformities.

- Place the ruler or tape measure across the widest part of the object, aligning one end of the ruler with the edge.

- Note the measurement where the opposite edge of the object aligns with the ruler or tape measure. This measurement represents the diameter of the object.

For better accuracy, it is recommended to take multiple measurements and calculate the average. This helps to minimize any errors that may occur due to slight variations in measurements.

Tips For Ensuring Accuracy

Obtaining accurate measurements is crucial, especially when precision is required. Here are some tips to ensure accuracy when measuring diameter using a ruler or tape measure:

- Hold the ruler or tape measure steady while taking measurements to avoid any unnecessary movement that may lead to inaccurate readings.

- Use a ruler or tape measure with clear and well-defined markings to make it easier to identify the measurement accurately.

- Avoid placing excessive pressure on the object being measured, as this can cause deformation and affect the accuracy of the measurement.

- If possible, use a ruler or tape measure with both metric and imperial measurements to cater to different measurement systems.

- Ensure proper lighting conditions to clearly see the alignment of the ruler or tape measure with the edges of the object.

By following these steps and tips, you can confidently measure the diameter of an object using a ruler or tape measure. Remember, accuracy is key, so take your time and double-check your measurements for reliable results.

Laser Diameter Measurement

Laser diameter measurement is a precise and efficient method used in various industries to accurately measure the diameter of objects. Using laser devices for diameter measurement offers several advantages, making it a popular choice for ensuring accuracy in manufacturing and quality control processes.

Advantages Of Laser Tools

1. High Precision: Laser devices provide accurate and reliable measurements, ensuring precision in diameter assessment.

2. Non-Contact: The non-contact nature of laser measurement eliminates the risk of damage to delicate or sensitive materials during the assessment process.

3. Speed: Laser tools can quickly and efficiently measure diameters, enhancing productivity in manufacturing processes.

How To Use Laser Devices For Diameter

1. Calibration: Ensure the laser device is properly calibrated to guarantee accurate measurements.

2. Positioning: Place the laser device at an optimal distance and angle to accurately capture the diameter of the object.

3. Data Analysis: Utilize the data collected by the laser device to calculate and verify the diameter of the object.

Online Calculators And Apps

Need to measure the diameter? Look no further than online calculators and apps. These handy tools provide a quick and easy way to accurately measure the diameter of any object without the need for manual calculations or guesswork. Get precise measurements in just a few clicks, making your tasks more efficient and accurate.

Convenience Of Digital Tools

Online calculators and apps offer quick and accurate measurements.

They provide instant results without the need for manual calculations.

These tools are user-friendly and accessible anytime, anywhere.

Recommended Apps For Diameter Calculation

App Name | Description

— | —

Diameter Calculator | Simple interface for easy diameter calculations

Circle Area & Circumference | Calculates diameter, area, and circumference

These apps are efficient and reliable for diameter measurements.

Common Mistakes To Avoid

When measuring diameter, it is important to avoid common mistakes. Follow these tips for accurate measurements: use the right tool, position it correctly, take multiple measurements for precision, be mindful of any deformities or irregularities, and double-check your calculations. By avoiding these mistakes, you can ensure accurate diameter measurements.

Avoiding Parallax Errors

Avoid parallax by aligning the measuring tool directly.

Eliminate viewing angle discrepancies for accurate measurements.

Position your eye perpendicular to the diameter for precision.

Ensuring Proper Tool Calibration

Calibrate measuring devices regularly for reliable results.

Check the calibration of the tool before each use.

Ensure the accuracy of the measuring instrument is maintained.

Common Mistakes to Avoid:

| 1. | Not aligning the measuring tool properly |

| 2. | Forgetting to calibrate the measuring device |

| 3. | Ignoring parallax errors during measurements |

| 4. | Using a damaged or inaccurate tool |

Practical Exercises And Examples

Learn how to measure diameter with practical exercises and examples. Discover step-by-step methods for accurate diameter measurements in real-world applications. Master the essential skills for determining diameter with precision and confidence.

Real-world Measurement Scenarios

Interactive Diameter Measurement Activities

Are you ready to dive into some practical exercises and examples related to measuring diameter? Let’s explore real-world measurement scenarios and interactive activities together!

In real-world scenarios, measuring the diameter of objects is essential for various applications, from engineering to construction. Practical exercises can help you master this skill.

Interactive activities are a fun way to enhance your understanding of diameter measurement. Let’s engage in hands-on exercises to improve your skills.

Real-World Measurement Scenarios:

– Measure the diameter of a circular table using a measuring tape.

– Calculate the diameter of a circle based on its circumference.

– Estimate the diameter of a ball by measuring its circumference.

Interactive Diameter Measurement Activities:

1. Online Tutorials: Explore interactive tutorials that guide you through measuring diameters step by step.

2. Virtual Simulations: Engage in virtual simulations where you can practice measuring diameters in a dynamic environment.

3. Measurement Apps: Use measurement apps on your smartphone to measure the diameter of objects around you.

By participating in these exercises and examples, you can sharpen your diameter measurement skills and apply them to real-world situations.

Advanced Techniques

When measuring diameter, advanced techniques like employing ultrasonic devices and understanding coordinate measuring machines can enhance accuracy and efficiency.

Employing Ultrasonic Devices

- Utilize ultrasonic devices to measure diameter with high precision.

- These devices use sound waves to determine diameter non-destructively.

Understanding Coordinate Measuring Machines

- Coordinate Measuring Machines ensure accurate measurements of diameter.

- These machines use a probe to gather data points for precise calculations.

Credit: www.hooverfence.com

Frequently Asked Questions

What Tools Are Needed To Measure Diameter?

You will need a caliper, micrometer, or ruler to measure diameter accurately.

Why Is It Important To Measure Diameter Correctly?

Accurate diameter measurement ensures proper fit and function of parts and components.

How Do I Measure The Diameter Of A Round Object?

Use a caliper to measure the widest point across the circle to determine the diameter.

Can Diameter Be Calculated From Circumference?

Yes, divide the circumference by π (pi) to calculate the diameter of a circle.

What Are The Common Units For Measuring Diameter?

The most common units for diameter measurement are inches, millimeters, and centimeters.

Conclusion

To sum it up, measuring the diameter may seem like a daunting task, but it can be done accurately with the right tools and techniques. Remember to choose the appropriate measuring instrument, take multiple measurements to ensure precision, and record your results properly.

Whether you are measuring the diameter of a pipe or a ball, following these steps will ensure accurate results. So, next time you need to measure diameter, don’t hesitate to put these tips into practice.